Plasmability Icemaker™

CVD Diamond Growth System

For Advanced Materials Applications:

Quantum, Electronics, Optics

Plasmability is now offering its IceMaker™ CVD diamond growth systems to select customers.

-

Unprecedented Growth: 10 mm thickness in a nonstop process.

-

Ultra-Stable Temperature Control: +/- 3°C for 800+ hours with no change of power, pressure, or chemistry.

-

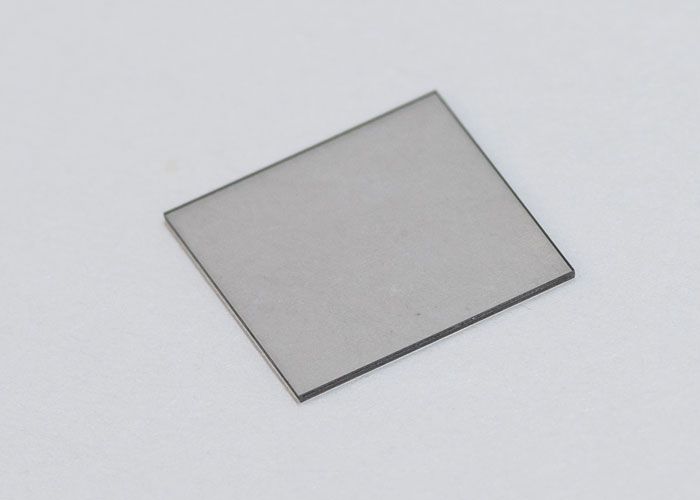

Precise Impurity Control: Ultra-low leak rates for superior films <1 ppb nitrogen.

-

Advanced Automation: Flexible recipe control, fully automated operation from start to finish, automated data collection, remote access.

Standard Features:

-

Dual-Wavelength Pyrometer: Real-time temperature measurement.

-

Dual Optical Cameras: Monitor growth in real-time.

-

Comprehensive Data Logging: Built-in data and video collection and push-to SQL Server capability.

-

Ultra-Clean Gas Panel with Digital MFC's: Enables precise epitaxial growth.

-

High-Accuracy Pressure Control: Dual capacitance manometers and pressure controller.

-

Reliable Pumping: Efficient and clean performance with dry scroll pumps.

Optional Features:

-

Flexible Power Configurations: Choose 6 kW or 10 kW 2.45 GHz.

-

Chamber Flexibility: Single or dual chamber configurations.

-

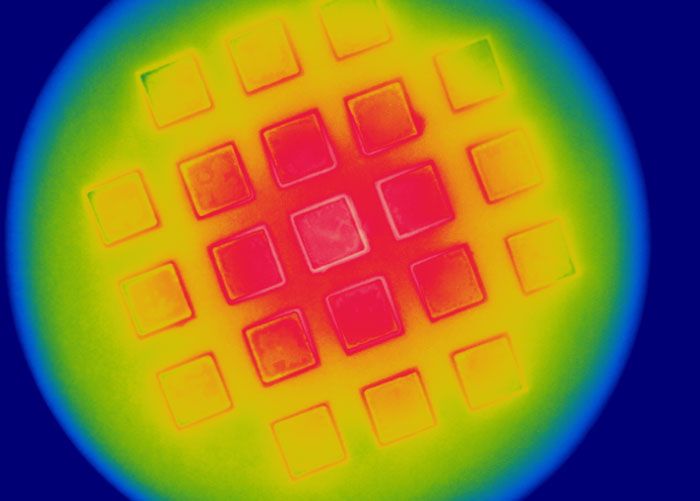

Thermal Camera: Large area temperature measurements.

-

Customer-focused solutions: Customization of hardware and software.

Our Facility

-

10 dual chamber systems (10 kW each chamber).

-

2 single chamber systems (10 kW each chamber).

-

3 laser cutting systems for customer samples.

-

Able to supply production quantities or samples of diamond material to customers.

Full-service

-

US-based

-

Experienced team for installation, field-service and process support.

-

Continuous process advancements from our internal foundry will support the customer.

Dual 10kW IceMaker Configuration (right chamber shown). Picture taken with onboard cameras.

Optional thermal camera

Single crystal sample <1 ppb of nitrogen

Examples of finished gems